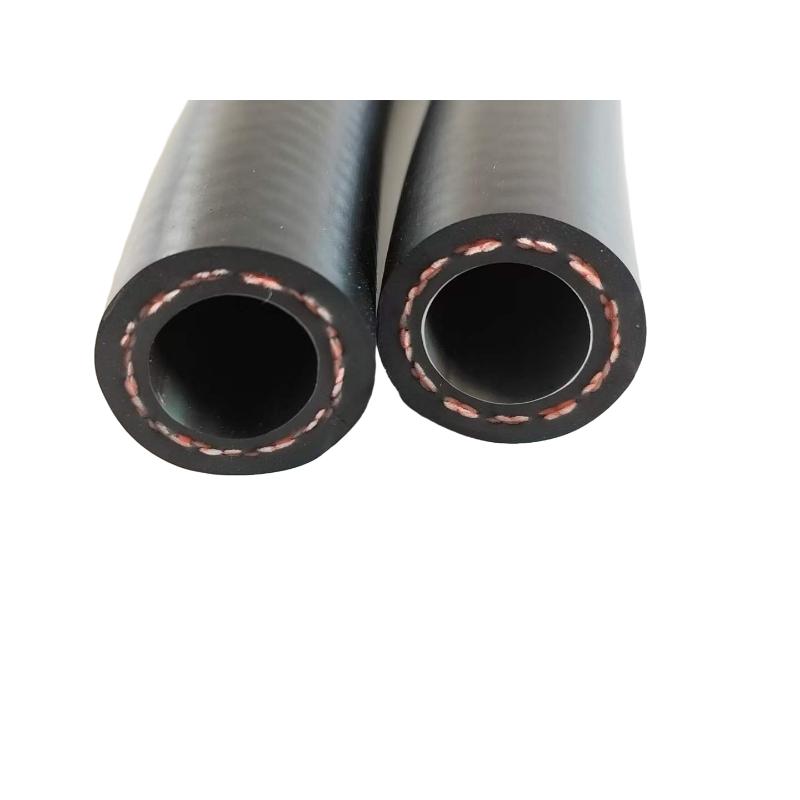

Ethanol blended fuel requires specialized rubber fuel hoses.

Jun . 13, 2024 11:07 Back to list

Ethanol blended fuel requires specialized rubber fuel hoses.

The Impact of Ethanol on Rubber Fuel Lines

Ethanol, a biofuel primarily derived from corn or other plant sources, has been increasingly used as an additive in gasoline to reduce our reliance on fossil fuels and decrease greenhouse gas emissions. However, its compatibility with rubber fuel lines has raised concerns in the automotive industry. This article delves into the relationship between ethanol, rubber, and fuel lines, exploring the potential consequences and solutions.

Ethanol's high corrosive nature, particularly its ability to absorb water, can pose a significant challenge to traditional rubber fuel lines. The ethanol-laden gasoline, commonly known as E10 (10% ethanol), can deteriorate rubber components over time, leading to cracks, leaks, and potential failure of fuel lines. The problem exacerbates with higher ethanol blends like E15 or E85, which contain 15% and 85% ethanol, respectively.

Rubber compounds that were once standard in fuel system components, such as neoprene, may not withstand the onslaught of ethanol. The ethanol can soften and swell the rubber, causing it to degrade and eventually disintegrate. This degradation not only affects fuel lines but also other rubber parts in the fuel system, including seals and gaskets.

The issue is compounded by the fact that many older vehicles, as well as small engines, were not designed to handle ethanol-blended fuels. These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards

These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards ethanol rubber fuel lines.

To mitigate this problem, the automotive industry has been researching and developing ethanol-resistant rubber compounds. Specialized elastomers, such as Viton, have shown resilience against ethanol's corrosive effects. These materials are specifically formulated to withstand the chemical attack of ethanol, ensuring the integrity of fuel lines even with prolonged exposure.

Moreover, vehicle manufacturers now design their cars with ethanol-compatible materials, and owners of older vehicles are encouraged to replace their rubber fuel lines with ethanol-resistant ones. Regular maintenance, including checking for signs of degradation and leaks, is also crucial.

In conclusion, while ethanol offers environmental benefits, its interaction with rubber fuel lines is a critical issue that needs attention. As we transition towards cleaner energy sources, it is essential to understand and address these compatibility challenges. The development of ethanol-resistant rubber and increased awareness among consumers and mechanics will play a vital role in ensuring the safe and efficient use of ethanol-blended fuels. It underscores the need for continuous innovation and adaptation in the face of changing fuel compositions.

ethanol rubber fuel lines.

To mitigate this problem, the automotive industry has been researching and developing ethanol-resistant rubber compounds. Specialized elastomers, such as Viton, have shown resilience against ethanol's corrosive effects. These materials are specifically formulated to withstand the chemical attack of ethanol, ensuring the integrity of fuel lines even with prolonged exposure.

Moreover, vehicle manufacturers now design their cars with ethanol-compatible materials, and owners of older vehicles are encouraged to replace their rubber fuel lines with ethanol-resistant ones. Regular maintenance, including checking for signs of degradation and leaks, is also crucial.

In conclusion, while ethanol offers environmental benefits, its interaction with rubber fuel lines is a critical issue that needs attention. As we transition towards cleaner energy sources, it is essential to understand and address these compatibility challenges. The development of ethanol-resistant rubber and increased awareness among consumers and mechanics will play a vital role in ensuring the safe and efficient use of ethanol-blended fuels. It underscores the need for continuous innovation and adaptation in the face of changing fuel compositions.

These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards

These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards These engines may have rubber fuel lines that are incompatible with ethanol, increasing the risk of damage and potential safety hazards ethanol rubber fuel lines.

To mitigate this problem, the automotive industry has been researching and developing ethanol-resistant rubber compounds. Specialized elastomers, such as Viton, have shown resilience against ethanol's corrosive effects. These materials are specifically formulated to withstand the chemical attack of ethanol, ensuring the integrity of fuel lines even with prolonged exposure.

Moreover, vehicle manufacturers now design their cars with ethanol-compatible materials, and owners of older vehicles are encouraged to replace their rubber fuel lines with ethanol-resistant ones. Regular maintenance, including checking for signs of degradation and leaks, is also crucial.

In conclusion, while ethanol offers environmental benefits, its interaction with rubber fuel lines is a critical issue that needs attention. As we transition towards cleaner energy sources, it is essential to understand and address these compatibility challenges. The development of ethanol-resistant rubber and increased awareness among consumers and mechanics will play a vital role in ensuring the safe and efficient use of ethanol-blended fuels. It underscores the need for continuous innovation and adaptation in the face of changing fuel compositions.

ethanol rubber fuel lines.

To mitigate this problem, the automotive industry has been researching and developing ethanol-resistant rubber compounds. Specialized elastomers, such as Viton, have shown resilience against ethanol's corrosive effects. These materials are specifically formulated to withstand the chemical attack of ethanol, ensuring the integrity of fuel lines even with prolonged exposure.

Moreover, vehicle manufacturers now design their cars with ethanol-compatible materials, and owners of older vehicles are encouraged to replace their rubber fuel lines with ethanol-resistant ones. Regular maintenance, including checking for signs of degradation and leaks, is also crucial.

In conclusion, while ethanol offers environmental benefits, its interaction with rubber fuel lines is a critical issue that needs attention. As we transition towards cleaner energy sources, it is essential to understand and address these compatibility challenges. The development of ethanol-resistant rubber and increased awareness among consumers and mechanics will play a vital role in ensuring the safe and efficient use of ethanol-blended fuels. It underscores the need for continuous innovation and adaptation in the face of changing fuel compositions.