Brake lines for trailers hydraulic system overview.

Bir . 14, 2024 14:43 Back to list

Brake lines for trailers hydraulic system overview.

Understanding Hydraulic Brake Lines for Trailers

Hydraulic brake systems are a crucial component of modern trailers, providing a reliable and efficient means of slowing down or coming to a complete stop. These systems rely on the principles of fluid dynamics to transmit stopping power from the towing vehicle to the trailer's wheels. Let's delve into the basics of hydraulic brake lines for trailers and their importance.

At the heart of any hydraulic braking system are the brake lines. These are essentially pipes that carry brake fluid from the master cylinder, which is activated by the driver, to the brake calipers or drums at each wheel of the trailer. The brake lines must be sturdy, leak-proof, and able to withstand the high pressures generated when the brakes are applied.

The operation of these hydraulic systems is quite straightforward yet ingenious. When the driver presses the brake pedal, it forces the piston in the master cylinder to move, thereby increasing the pressure within the system. This pressurized fluid cannot compress and thus transfers the force along the closed system to the slave cylinders at the wheels. Here, the pressure is converted back into mechanical force, clamping the brake pads against the rotors or forcing the shoes against the drums to create friction, which slows down the trailer.

It's essential for the brake lines to be free from any blockages or leaks since even a small disruption in fluid transmission can lead to a disproportionate response at the brakes or, worse, failure to engage them altogether. That's why regular inspection and maintenance of these lines are critical for safety on the road That's why regular inspection and maintenance of these lines are critical for safety on the road That's why regular inspection and maintenance of these lines are critical for safety on the road That's why regular inspection and maintenance of these lines are critical for safety on the road

That's why regular inspection and maintenance of these lines are critical for safety on the road That's why regular inspection and maintenance of these lines are critical for safety on the road hydraulic brake lines for trailers.

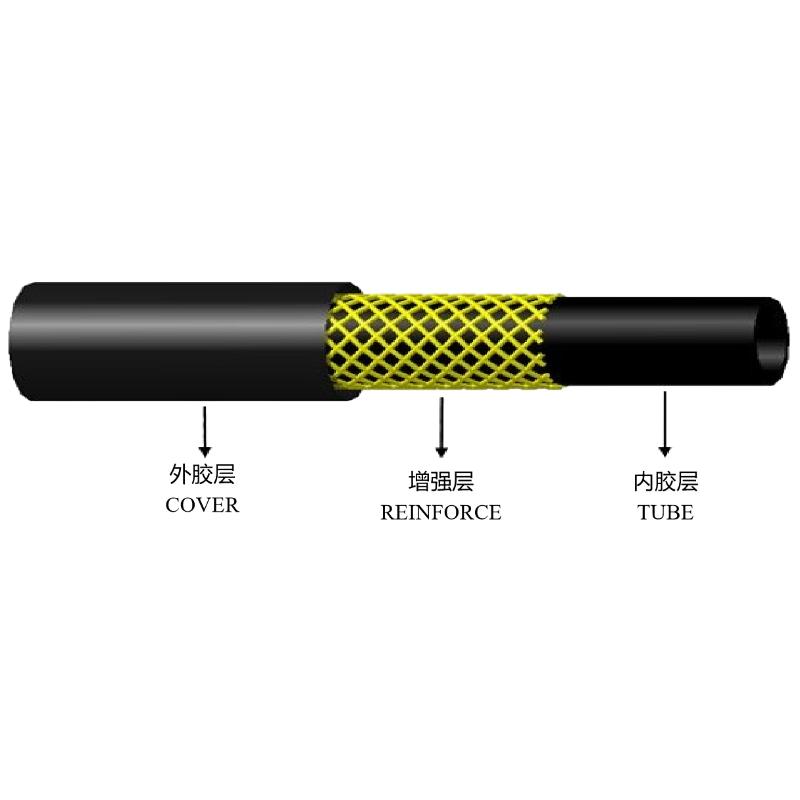

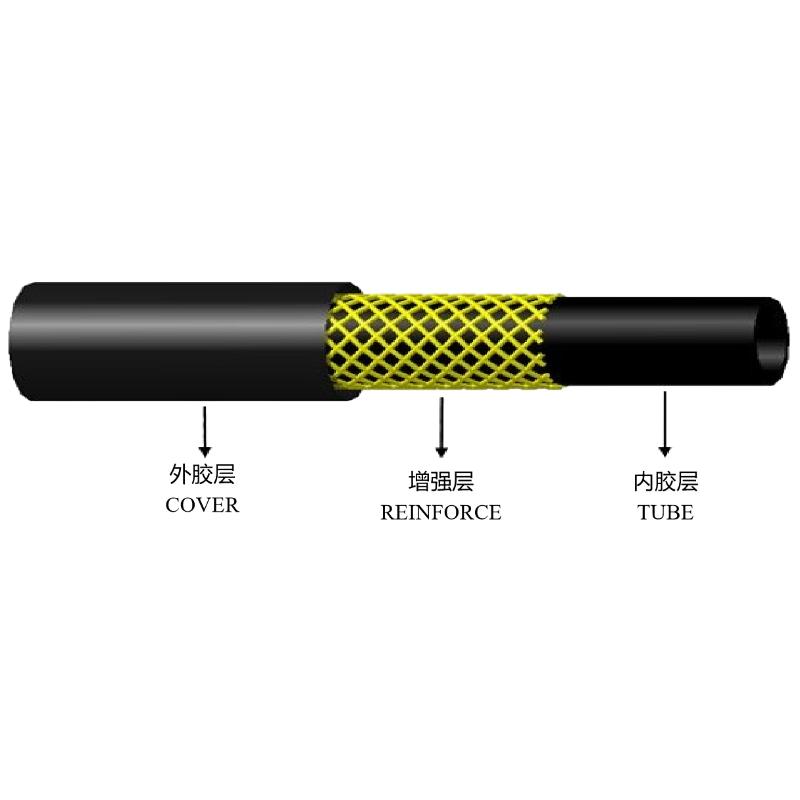

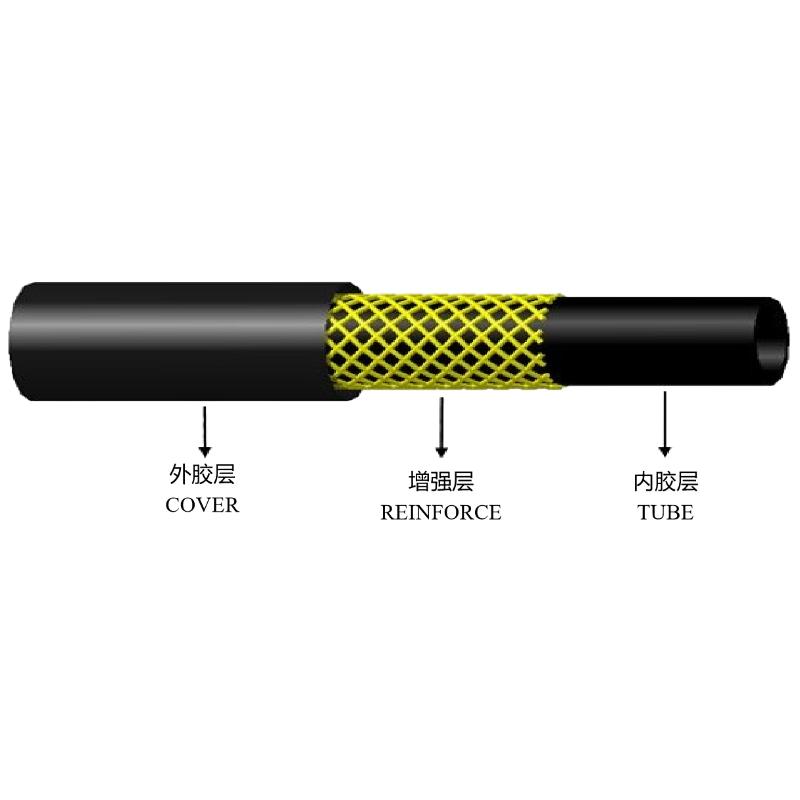

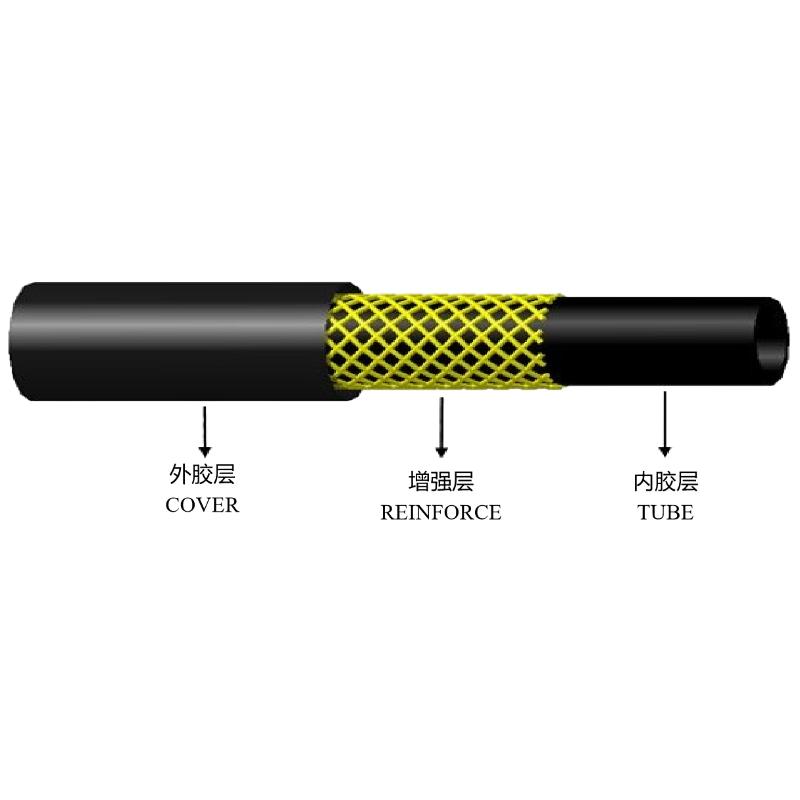

In terms of materials, brake lines are typically made from steel or brass, with steel being more common due to its strength and durability. They are often coated with a protective layer to prevent corrosion and ensure longevity. High-pressure hoses might also be used in certain applications, especially where flexibility is required, such as near joints or between parts that move relative to each other during normal operation.

When it comes to installation, precision is key. The brake lines must be routed correctly to avoid kinks, which can restrict fluid flow, and secured firmly to prevent chafing or damage from road vibration. Proper flaring of the pipe ends ensures a tight seal at connections, preventing leaks that could compromise brake performance.

In conclusion, while the workings of hydraulic brake lines may seem simple, their role in ensuring the safe towing of trailers is paramount. Regular checks, using quality components, and proper installation techniques all contribute to a reliable braking system. For those who use trailers frequently, understanding the basics of hydraulic brake lines can empower owners to perform routine inspections and troubleshoot minor issues before they become major problems, keeping everyone safer on the road.

hydraulic brake lines for trailers.

In terms of materials, brake lines are typically made from steel or brass, with steel being more common due to its strength and durability. They are often coated with a protective layer to prevent corrosion and ensure longevity. High-pressure hoses might also be used in certain applications, especially where flexibility is required, such as near joints or between parts that move relative to each other during normal operation.

When it comes to installation, precision is key. The brake lines must be routed correctly to avoid kinks, which can restrict fluid flow, and secured firmly to prevent chafing or damage from road vibration. Proper flaring of the pipe ends ensures a tight seal at connections, preventing leaks that could compromise brake performance.

In conclusion, while the workings of hydraulic brake lines may seem simple, their role in ensuring the safe towing of trailers is paramount. Regular checks, using quality components, and proper installation techniques all contribute to a reliable braking system. For those who use trailers frequently, understanding the basics of hydraulic brake lines can empower owners to perform routine inspections and troubleshoot minor issues before they become major problems, keeping everyone safer on the road.

That's why regular inspection and maintenance of these lines are critical for safety on the road That's why regular inspection and maintenance of these lines are critical for safety on the road

That's why regular inspection and maintenance of these lines are critical for safety on the road That's why regular inspection and maintenance of these lines are critical for safety on the road hydraulic brake lines for trailers.

In terms of materials, brake lines are typically made from steel or brass, with steel being more common due to its strength and durability. They are often coated with a protective layer to prevent corrosion and ensure longevity. High-pressure hoses might also be used in certain applications, especially where flexibility is required, such as near joints or between parts that move relative to each other during normal operation.

When it comes to installation, precision is key. The brake lines must be routed correctly to avoid kinks, which can restrict fluid flow, and secured firmly to prevent chafing or damage from road vibration. Proper flaring of the pipe ends ensures a tight seal at connections, preventing leaks that could compromise brake performance.

In conclusion, while the workings of hydraulic brake lines may seem simple, their role in ensuring the safe towing of trailers is paramount. Regular checks, using quality components, and proper installation techniques all contribute to a reliable braking system. For those who use trailers frequently, understanding the basics of hydraulic brake lines can empower owners to perform routine inspections and troubleshoot minor issues before they become major problems, keeping everyone safer on the road.

hydraulic brake lines for trailers.

In terms of materials, brake lines are typically made from steel or brass, with steel being more common due to its strength and durability. They are often coated with a protective layer to prevent corrosion and ensure longevity. High-pressure hoses might also be used in certain applications, especially where flexibility is required, such as near joints or between parts that move relative to each other during normal operation.

When it comes to installation, precision is key. The brake lines must be routed correctly to avoid kinks, which can restrict fluid flow, and secured firmly to prevent chafing or damage from road vibration. Proper flaring of the pipe ends ensures a tight seal at connections, preventing leaks that could compromise brake performance.

In conclusion, while the workings of hydraulic brake lines may seem simple, their role in ensuring the safe towing of trailers is paramount. Regular checks, using quality components, and proper installation techniques all contribute to a reliable braking system. For those who use trailers frequently, understanding the basics of hydraulic brake lines can empower owners to perform routine inspections and troubleshoot minor issues before they become major problems, keeping everyone safer on the road.